TestStation Product Family

Fastest In-Circuit Test Platform

Teradyne’s TestStation in-circuit test systems provide electronics manufacturers with reliable high-quality, high-volume testing for the latest printed circuit board assembly (PCBA) technologies that are used in automotive, industrial, computing, consumer, communications, and defense end-products.

TestStation In-Circuit Test Systems provide full structural and functional coverage for a wide-range of manufacturing, component, process, and performance for high-performance analog, digital, and mixed-signal devices used on modern PCBs.

TestStation models can be configured specifically for the following end-product testing:

- High-Reliability Products: Automotive and Industrial applications that require extreme fault detection capability and parts-per-billion defect rates for the end-consumer

- High-Complexity Products: Network, Computing, and Communications applications tests that incorporate large number of devices and require capability beyond 5,000 test points

- High-Volume Products: Consumer and Wireless applications that require extremely low cost of test and no-touch manufacturing solutions

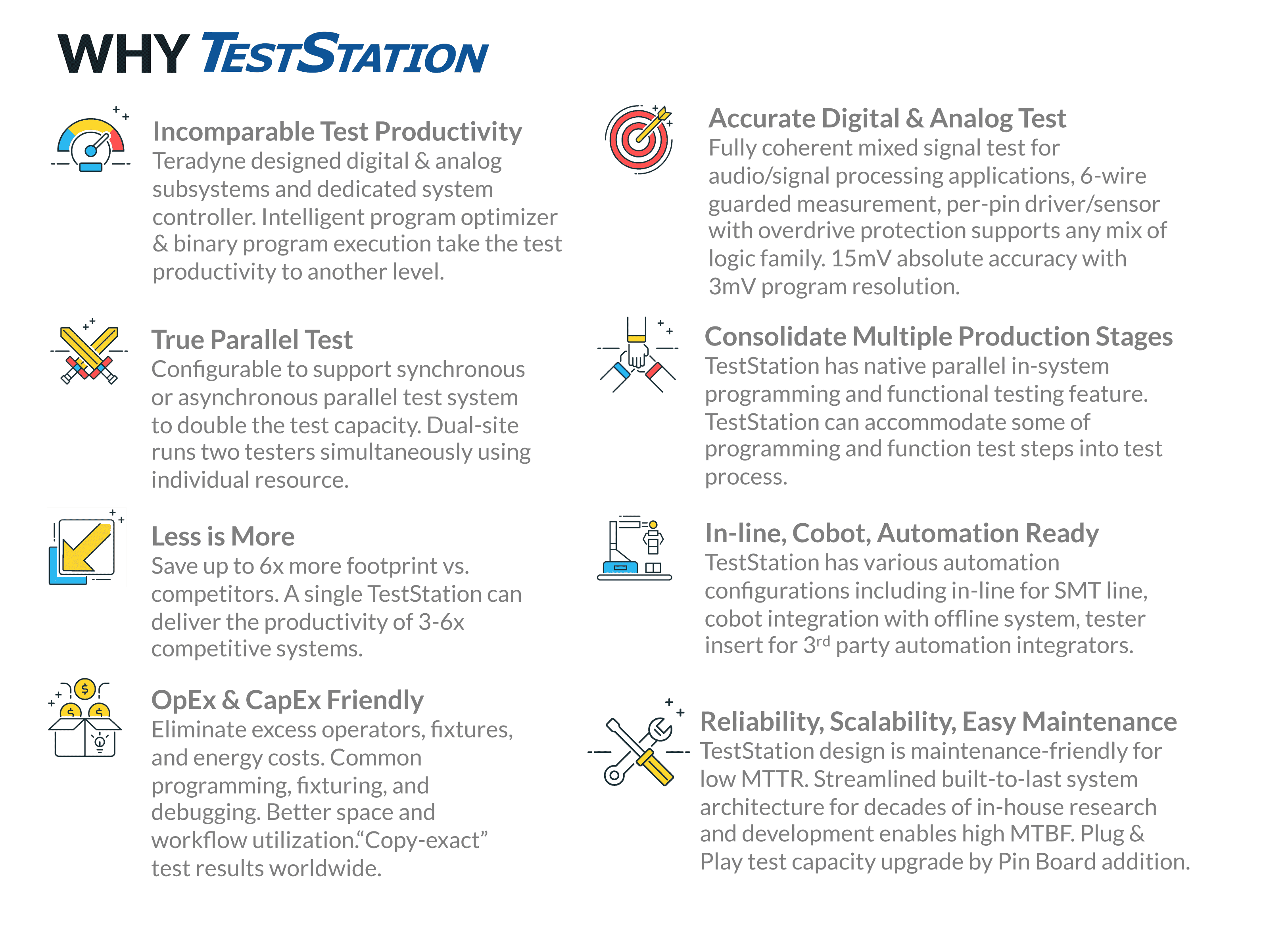

Teradyne’s TestStation family of production board test systems offers solutions to fit any PCBA manufacturing line requirement. Merging defect removal, boundary scan, power-on BIST, parallel device flashing and functional pre-screen capability, TestStation can merge multiple costly test stages into a single, optimized solution.

The Teradyne TestStation Advantage

TestStation is a scalable design that allows users to easily configure size, pin count, instrumentation, automation options, and other test features to match your specific test needs to satisfy throughput and budget requirements.

Capable: Configurable for ICT, boundary scan, ISP, flash programming, and functional test

Flexible: Multiple system sizes, options, pin counts, and automation options

Scalable: Common test architecture with consistent hardware options and software environments across system models