Production Board Test

Repair Station Software

Teradyne Repair Station Software is a paperless repair, defect tracking and reporting tool designed by Siemens Electronic Manufacturing Solutions group specifically for Teradyne TestStation in-circuit test systems. Teradyne Repair Station software offers graphical paperless repair, defect tracking and manufacturing quality reports.

Advantages

Automated Data Collector

- Real-Time data capture of fault and diagnostic information

- Reports of all boards waiting repair and the repair cycle times

- Fault and verified fix information available for analysis in real-time via web reports

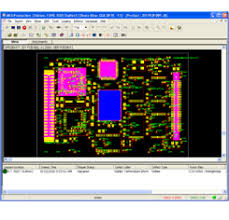

Point-and-Click with PCB Layout and Schematic

- Displays graphical layout and visual aids for repair

- Simple and intuitive interface for all levels of experience

Powerful Tools for Quick PCB Debug with REPAIR ADVISOR

- Cross-probe between layout and schematic views

- Quickly search and highlight by part number or reference designator

Key Features

- Electronic representation of tester failure ticket

- Automatic capture of defect data

- Assists with root cause analysis and repair processes

- Records rework/repair

- Provides real-time and historical reporting

- Board Serial Number

- Pass/Fail time stamps

- Failure repair ticket

- Diagnostic information

System Requirements

The lightweight implementation supports installation and licensing of the software on individual repair stations on the manufacturing floor. Ultimate flexibility is supported in the setup of each repair station as the software supports having a single database associated with multiple testers or dedicated databases for each tester on the manufacturing floor. No additional software or licenses are required on the Teradyne test system – the requirement is that the Repair Station Software must be installed and licensed for each repair station PC setup on the manufacturing floor. The software requires that the repair station PC be running the Microsoft Windows XP or Windows 7 operating system.